ENGINEERED HARDWOOD

- By Tom Petridis

- •

- 04 Feb, 2019

- •

What is Engineered Hardwood

I still have many people questioning the construction of engineered hardwood flooring. Most arguments are that it's "like" laminate. Engineered hardwood is "not" laminate flooring.

In order to understand what engineered hardwood is, we must understand the properties of wood. Wood is a live product and interacts with its environment. What does that mean?

Since wood is a porous material, it absorbs moisture during some seasons and releases moisture in other seasons. This is the main reason for acclimating the wood in your house for at least 48-72h.

When the wood absorbs the moisture thru humidity, it causes the wood to expand. When it releases the humidity during dry seasons, this causes the wood to contract. Wood is fairly stable along its longitudinal direction, parallel to the grain, shrinking only 0.01 percent of its length as it dries. Wood moves much more across the grain, shrinking as much as 8 percent in this direction. Since we understand that there is now movement in wood, especially in "across the grain" and since we know its approx. 8% of its total size, what do you think would happen when we begin to increase the width of our beautiful wide planks from 3" to 12"?

Traditionally, hardwood strips were 1.5" wide to 3" wide, have you ever asked yourselves why? Because on a 1.5" wide plank, 8% of shrinkage is 0.12" or 1/8th of an inch. (Not so bad, right)... As manufactures started increasing the width sizes of the planks to 3-4-5" that gaps began to grow significantly wider and more noticeable during winter seasons. Because the look with wide gaps wasn't desirable in the past and the trend was becoming wider in widths, engineers had to come up with a solution.

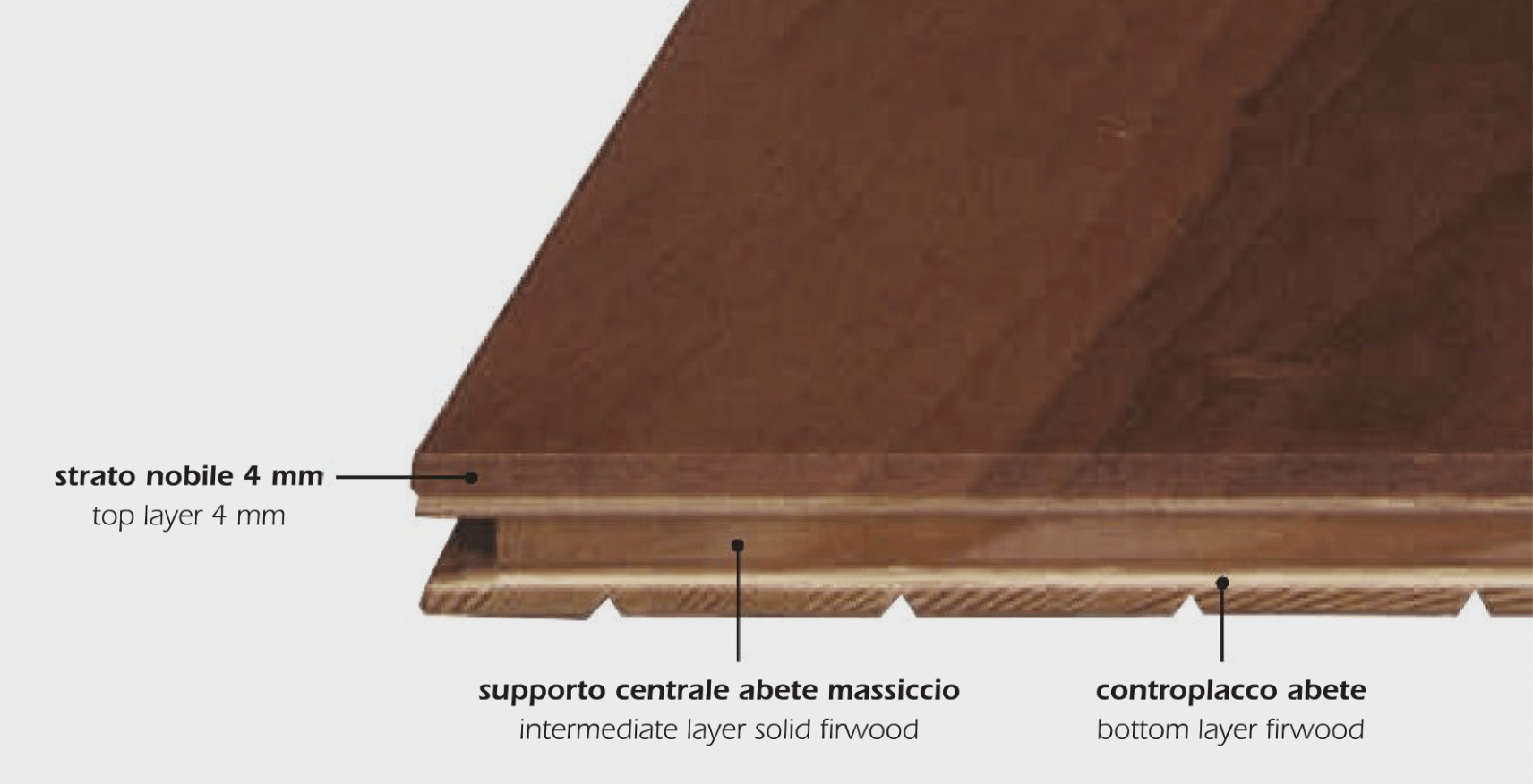

What they came up with, was to create a sandwiched wooden product. Engineered hardwood flooring is made of layers of wood, (not MDF or composite) bonded together with adhesives under intense heat and pressure. Each layer is glued perpendicular to the other preventing it to shrink or expand, which makes it resistant to warping and cupping, (when the top layer wants to expand or shrink one direction, the one below it, is forcing it to go the other direction) therefore creating a more stable floor. The top layer is the desired species of wood while the middle and sometimes lower pieces are made from other species. (look at the diagram above)

Most people will ask "How many times can you sand it?" (as if they sand it once a year?!?!) and my answer is, if you buy an engineered flooring with 4 or more millimeters as a top layer, then you can easily sand it as many times as a solid wood floor. Up to 3x max. (depending on previous colour) Most people think they can sand solid hardwood indefinitely, but this is not true. Once solid wood reaches the tougne and groove portion of its sanding life, its over. usually this top layer is about 4-5mm. (same as the engineered)

In my opinion, if you are not after that rustic or gappy look, and love a wide plank style look, then you are making a huge mistake if you are not considering engineered product.